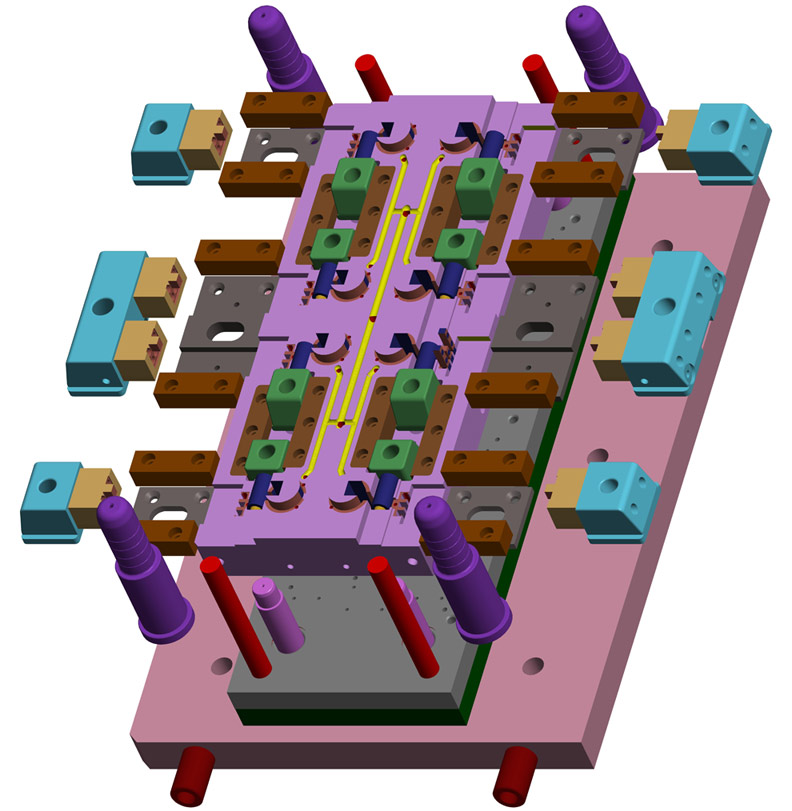

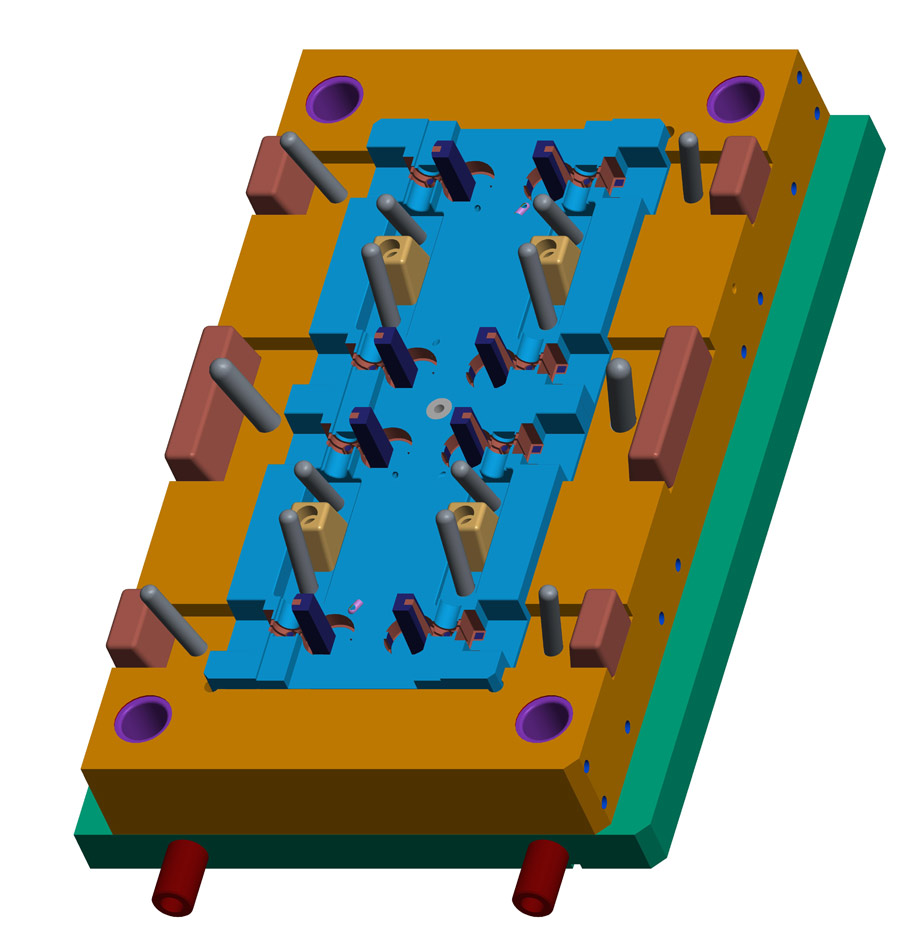

Tooling

We can provide a complete solution from initial design through to finished components.

We have developed a system of Toolmaker, vendor and designer which works in tandem with each other for better production. In each stage of production, especially in the beginning stage, special attention is given to the design of moulds.

Our flow path analysis program helps us to design optimum production friendly moulds so that we can offer our products to our customers for best price and meet the specifications.

We always follow the basic project management principles to ensure smooth flow of operations so that we can deliver the products on time.

Kunststoff have formed strategic alliances with a number of trusted toolmakers to enable competitive quotations that are delivered on time and to budget.

In Kunststoff, normally we use High Hard P20 material for soft moulds and H13 for hardened moulds with standard mould base from reputed manufacturer.

Some time we also use different grades of steel as per plastic material that are going to be used along with Hot Sprue or Hot Runner Systems.